Innovative and sanitisable design

The sanitisable design and robust materials used make these reelstands state-of- the-art equipment. The only maintenance required to maintain their initial appearance and performance is regular cleaning.

INOXTRUCK by ULMA LIFTING SOLUTIONS

INOXTRUCK by ULMA LIFTING SOLUTIONS

MRS400

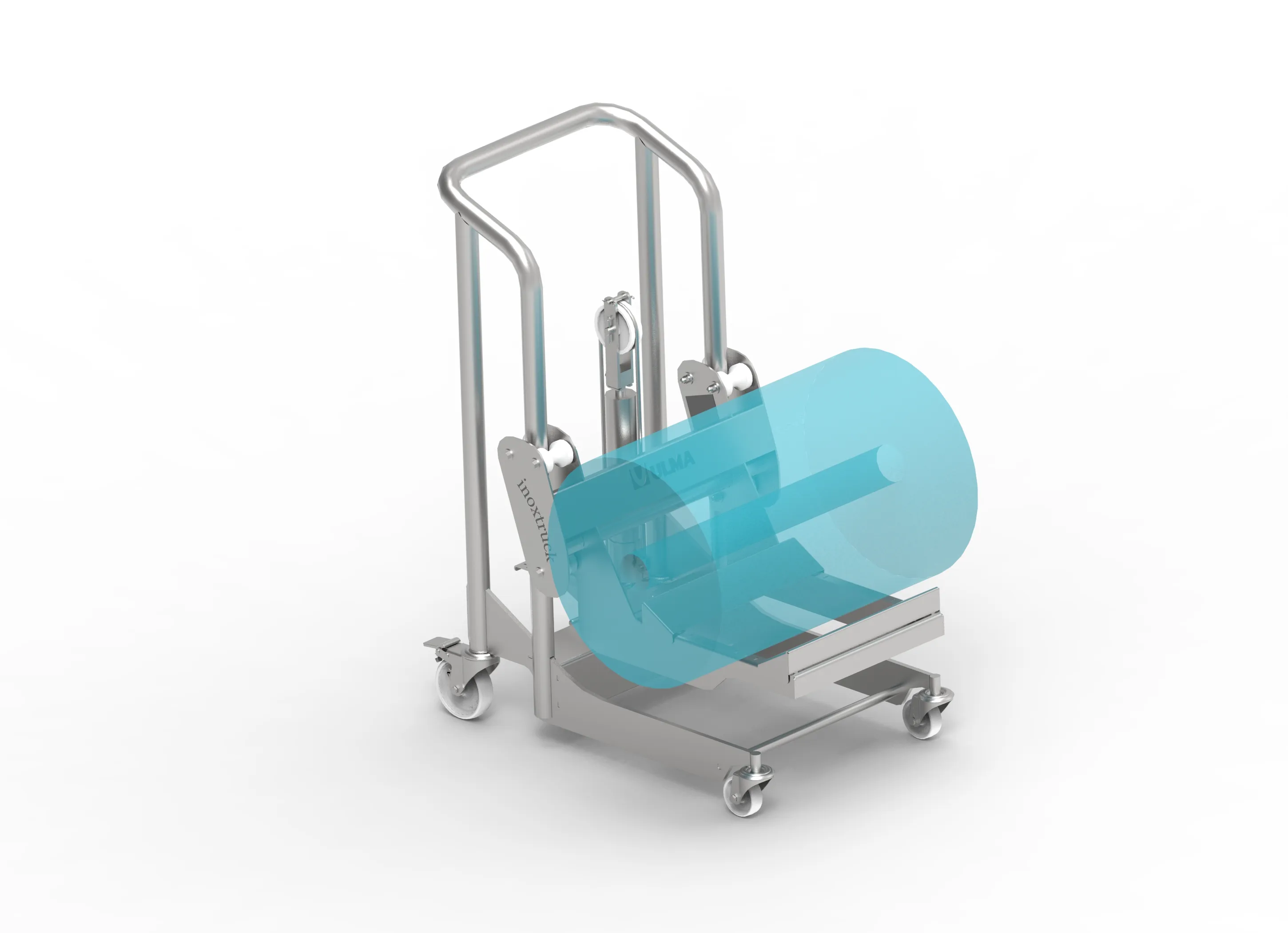

The Inoxtruck Bottom roll trolley MRS400 has been designed and manufactured to make the tough task of changing reels at a low height on food packaging machines more ergonomic. The fast hydraulic lifting system makes reel changeover quick and ergonomic, reducing time and high costs due to operator injuries.

Product

Bottom Roll Trolley

Manufacturer model

MRS400

Height

450 mm

Load

400 kg.

The sanitisable design and robust materials used make these reelstands state-of- the-art equipment. The only maintenance required to maintain their initial appearance and performance is regular cleaning.

The height and dimensions of the handle are ergonomically designed to ensure optimum handling of the trolley. The front wheels with brakes make loading and unloading the reel a safe operation.

Made entirely of stainless steel, including chassis, trolley and hydraulic equipment AISI 304L or 316L.

The trolley lifting system is designed for lateral and frontal movement of the reel. The two wedges with an easy and quick clamping system make it possible to fit reels of different width and length diameters.

INOXTRUCK

ULMA Lifting Solutions

FORKLIFT TRUCKS

USED MACHINERY

SPARE PARTS